Enhanced human body response to implants

UPM researchers have developed a new surface treatment that, applied to biomaterials, will allow us to reduce the implant rejection by our body. This will extend the prosthesis life and thus increase the quality of life of patients.

In an article published in the Scientific Reports journal, researchers from Centre for Biomedical Technology at Universidad Politécnica de Madrid (CTB-UPM) have developed a new technology that will allow them to modify the surface of metallic biomaterials in order to improve their interaction with the biological medium.

The procedure, called Activated Vapor Silanization (AVS), consists in coating the material surface with a layer of less than one-thousandth of a millimeter and joining molecules that are naturally found in our organism. This, applied to materials used to manufacture prosthesis, will reduce implant rejection and, and consequently, it will increase its useful life.

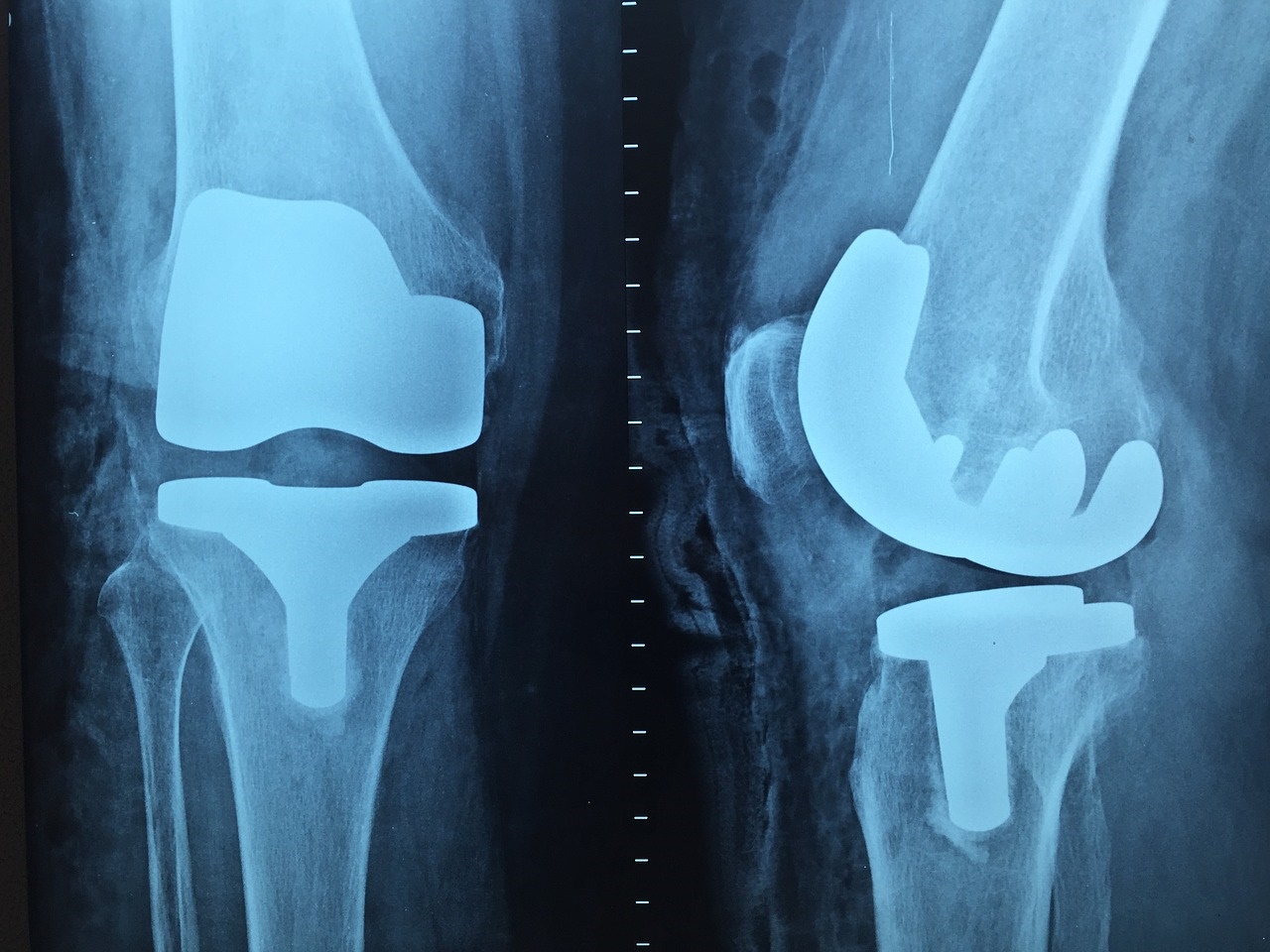

Credit: pixabay

Our organism is the result of a process through which our ancestors adapted to an external environment that was eminently hostile. As a result of this process, the exposure to any substance which is not essential for the survival is a threat and it leads to an aggressive response.

This mechanism, vital for our survival, has become a wall that is necessary to overcome for the development of any therapy that involves direct contact of a material with a human organ or tissue. This situation strongly restricts the number of materials available for medical use that in the case of metals are only three types: stainless steel, cobalt-based alloys, and titanium alloys.

Metallic biomaterials are essential in the prosthesis that are subjected to high stresses, such as hip and knee prostheses. However, even the metals used in medicine do not provoke an optimal reaction in our organism. The natural response of our body to these metallic biomaterials tends to coat them with a kind of scar that isolates the material from the surrounding functional tissues.

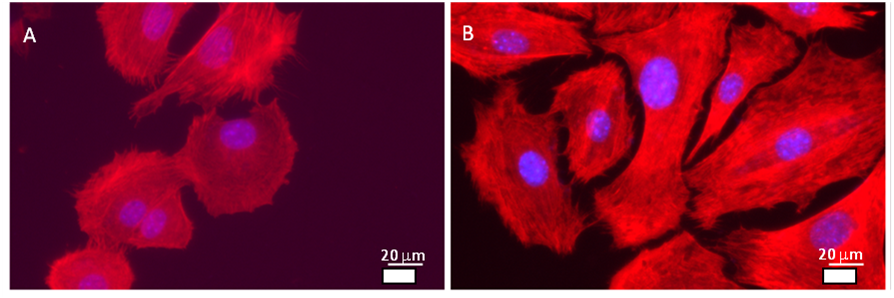

Proliferation of mesenchymal stem cells on (A) titanium alloy without treatment and (B) titanium alloy subjected to the AVS biofunctionalization treatment. Credit: UPM.

Such a scar can result in a short-term problem because it eases the appearing of an infection in the area of the prosthesis. Another long-term issue would be the implant loosening. As a consequence, a frequent solution to both situations is another surgery. Given all this information, it seems clear the need of establishing a close and reliable contact between the material and the surrounding functional tissue. As a result, we would reduce the implant rejection and increase its useful life.

This was the aim of this study carried out by researchers from the lab of Biomaterials and Regenerative Engineering from CTB-UPM. They have developed a new technique called Activated Vapor Silanization that allows them to place a layer less than one micron thick on the surface of metallic biomaterials easing thus the join of molecules naturally found in our organism.

Particularly, they observed that by immobilizing collagen molecules on a surface of titanium alloy they achieved a higher number of cells growing on the material as well as a larger size of such cells.

According to José Pérez, a researcher involved in this study, “the AVS technology is a versatile procedure that can be easily adapted to the procedures currently used to develop metallic biomaterials”. Therefore, the use of this technology can significantly improve the quality of life of patients that will require prosthesis in the future.

Rezvanian, P; Daza, R; Lopez, PA; Ramos, M; Gonzalez-Nieto, D; Elices, M; Guinea, GV; Perez-Rigueiro, J. Enhanced Biological Response of AVS-Functionalized Ti-6Al-4V Alloy through Covalent Immobilization of Collagen. SCIENTIFIC REPORTS, 8 10.1038/s41598-018-21685-3 FEB 20 2018