Brief description of the solution and the added value it delivers

The LAT-UPM High Voltage Laboratory team, located at the Universidad Politécnica de Madrid’s (UPM) School of Engineering and Industrial Design (ETSIDI), has developed a measuring procedure and instrument for analysing partial discharges in order to determine the state of insulators in high-voltage electrical networks.

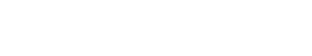

The technology they have developed, known by the trade name BlueBOX, represents a major step forward in improving and optimising the performance of electrical systems. It is notable for the application of advanced measuring techniques and the use of powerful numerical tools to effectively diagnose the state of the electrical insulators when carrying out tests on-site and with the installations online. This is of particular interest to electricity companies from a technical and economic point of view.

Description of the technological basis

Partial discharge testing has been shown to be an effective way of diagnosing the state of high-voltage insulators when the testing is carried out in a laboratory or even on site (with the installations to be tested offline and with low levels of electrical noise). However, the possibility of performing effective diagnoses while carrying out testing on site and with the installations online is currently of particular interest to electricity companies, as it represents a significant improvement in their ability to assess their assets and a reduction in the associated costs.

Carrying out online testing requires the application of advanced measurement and signal processing technologies that are capable of dealing with the inherent difficulties of this type of testing. Using BlueBOX technology, it is possible to overcome those difficulties, achieving satisfactory results as regards improving the performance of electrical systems.

‘BlueBOX technology represents a major step forward in the effective provision of reliable diagnoses of the state of dielectrics, which will result in an improvement in the state of high-voltage electrical installations’

Business needs / application

Companies involved in electricity generation, transmission and distribution.

-

For companies in the sector, it is of vital importance to know the state of the different assets that make up their installations, applying appropriate and economical management and maintenance policies for this purpose.

Companies that manufacture and install industrial equipment integrated into electricity networks.

-

Before an electrical installation is placed in service, it is necessary to detect any defects in the insulation that may have arisen, either during manufacturing or during assembly on site.

Control bodies and asset inspection and maintenance companies.

-

In order to ensure that installations meet the required quality standards throughout their useful life, periodic inspections must be carried out and effective maintenance plans put in place by authorised specialist companies.

Major consumers of electricity.

-

As it is of particular interest to such consumers that the electricity supply is guaranteed at all times, they need to adopt appropriate maintenance policies.

Improving the performance of electrical systems is now possible using BlueBOX technology to assess dielectrics, with the advantage that the installations can remain online

Competitive advantages

-

Providing accurate diagnoses of the state of electrical insulators, performing online partial discharge measurements by applying advanced and complementary measurement techniques and efficient signal processing tools.

-

Effective diagnosis in online testing implies:

-

Predicting insulation faults before they occur, without needing to interrupt the electrical service in the installations.

-

An increase in networks’ assessment capacity and efficacy and a decrease in the associated costs of between 30 and 45%.

-

Temporary or permanent real-time monitoring of the installations when in service.

-

Low initial investment, as the testing voltage is that of the network itself.

References

-

The current users of BlueBOX technology include major companies in the electricity sector (Gas Natural Fenosa, Iberdrola, Endesa, Red Eléctrica and Viesgo), other companies related to the sector (General Cable, Cotradis, LCOE, Doel, etc.) and companies that are major consumers of electricity and require continuity of supply (Aena, Alcoa, Metro de Barcelona, etc.).

Industrial protection

-

European patent applied for through the EPO: EP2579056.

-

Patent granted in Mexico: MX/a/2012/013801.

Stage of development

- Concept

- Research

- Lab prototype

- Industrial prototype

- Production

Contact

BlueBOX contact

Fernando Garnacho Vecino

e:

UPM contact

Innovation and Entrepreneurship Programmes

Technological Innovation Support Centre (CAIT) – UPM

e: