Brief description of the technology solution and the added value it provides

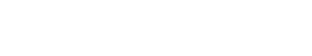

A multididsciplinary research team from CIME (Structural Materials Research Centre) has developed a new hybrid material technology, comprising metal plates and a fibre reinforced polymer core. It offers a light structural material with an increased structural efficiency and safety, as an alternative to the traditional materials used in the maritime, offshore, civil engineering and military markets.

Malecón© structures have a superior performance under in-service loads, improved fatigue and corrosion resistance, reduced weight, and provide damping to structure borne vibration and noise. Malecón offers an increased resistance to accidental and impact loads, and a built-in fire protection, with substantial improvements in safety and a reduction in environmental risk.

Description of the technological base

Steel has certain limitations that impede continued improvements targeted to construct light, resistant and safe structures. Composite materials are light and resistant, but the manufacturing processes are more labor-intensive and costly; in addition they are very sensitive to damage from impact and can present problems of degradation of mechanical properties through water absorption. Fiber-metal hybrid materials combine a high resistance to impact, an extended durability, and the versatility in processing of metals with a specific strength and stiffness in the direction parallel to the fibers, as well as good resistance to fatigue, characteristics of the composites.

MALECON© is a new hybrid fiber/metal material formed by layers of metal alternating with others of composite and structural adhesives, with improved in-service performance.

“Reducing construction and operating costs, and keeping the safety standards. These advantages are key factors in selecting Malecon© for lightweight structural applications”

Market demands

Maritime and defense markets

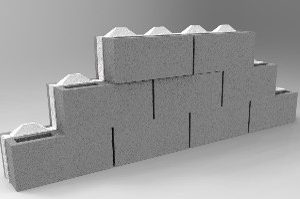

- In the old art of naval construction only one revolution took place, the step from wood to steel, but perhaps we are in the second revolution, the use of hybrid materials in similar manner like in aerospace industry. New materials for ships, capable of satisfying all the design and fabrication requirements for lighter structures that are in turn more resistant, permit higher speeds of movement and lower energy consumption. Repair of existing vessels also can be improved with the use of MALECON© .

Civil engineering and offshore industries

- A promising area of application is the design of sandwich-towers for wind energy converters (WEC). However, the requirements on the supporting structures will be also increased with the development of bigger turbines, especially in offshore parks. A tower section made of MALECON© offers some advantages with regard to the stability and structural integrity.

- It is necessary to look for new strategies for damage mitigation when high density materials and/or thick sections are not a viable option. MALECON© offers an outstanding energy absorption capability, using mechanisms that work at different length scales. These are of paramount importance for several industrial applications as bridges, floors, stadia terraces, storage tanks, modular buildings, etc.

“In lightweight designs, weight reduction by using hybrid materials will reduce CO2 emission and increase fuel economy, which will significantly reduce environmental impact”

Competitive advantages

- A material tailored to meet the most demanding needs of every structural application, on an individual basis.

- Improved fatigue life and corrosion resistance.

- Reduced weight of structures up to 40% (depending on applications).

- Provide damping to structure borne vibration and noise.

- Reduces construction and operating costs, keeping the safety standards.

- Manufacturing is less time consuming, and it shortens erection and repair schedules.

Development stage

- Concept

- Research

- Lab prototype

- Industrial prototype

- Production

Contact

Contacto MALECON©

Juan Carlos Suárez Bermejo

ETS Navales – UPM

e:

Contacto UPM

Área de Innovación, Comercialización y Creación de Empresas

Centro de Apoyo a la Innovación Tecnológica – UPM

e: