Brief description of the solution and the added value it delivers

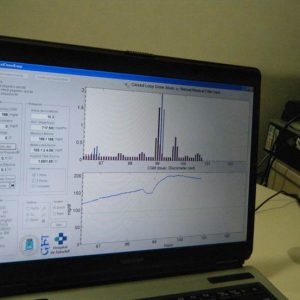

We have designed a rubber-cement composite with a high level of mechanical strength, with which we produce environmentally friendly concrete bricks that reduce the carbon footprint and improve the thermal comfort of buildings. Neoblock improves on the compressive mechanical properties of traditional building materials by a factor of between 2 and 10. It reduces the annual energy consumption of single-family homes by between 15 and 58% and, compared to other competing materials, improves the homes’ interior comfort by between 2 and 10ºC, depending on their location and the summer/winter conditions affecting them.

Description of the technological basis

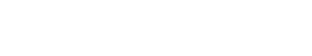

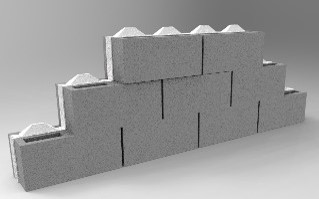

A composite engineering material has been designed that contains recycled rubber from discarded tyres. That material is used to produce Neoblock, a hybrid building material in the form of insulated concrete bricks.

The rubber reduces the material’s environmental footprint and increases its mechanical strength and resilience. Compressive strengths of more than 35 MPa and flexural strengths of more than 8 MPa were obtained. Plus, thanks to its internal realignment, it was found to be highly TOUGH and RESILIENT.

Other features of Neoblock are: elimination of thermal bridges, reduction in the energy consumption related to heating and cooling, and the consequent reduction in greenhouse gas emissions.

The correct use of this waste-based material in itself represents a significant technological advance, as the mechanical properties of concretes using this type of material as an aggregate had not previously been improved.

‘By including rubber, we reduce the material’s environmental footprint and increase its mechanical strength and resilience.’

Business needs / application

-

Constant population growth globally makes it necessary to improve the materials and systems used to build homes and other buildings.

-

Improving energy efficiency and reducing environmental impact: the cornerstone on which the development of new construction technologies is based.

-

Tendency on the part of the end user to demand building systems that result in lower costs (heating/cooling).

-

In Mexico, more than one million homes are built every year (70% social housing). More than 40% of their owners think that improvements relating to thermal insulation, sound insulation and wall strength are needed.

-

In Latin America, not all homes have heating/cooling systems to ensure the thermal comfort of their occupants.

Competitive advantages

-

Environmentally friendly: made with rubber from discarded tyres, which enables it to be assessed positively in international environmental certification processes (LEED, BREEAM, etc.).

-

Great mechanical strength (compressive strength of 35 MPa and flexural strength of 8 MPa), improving on the compressive strength of competing materials by a factor of up to 10.

-

Hybrid: its composition includes an insulating material. It ensures the elimination of thermal bridges and, thanks to its low thermal transmittance (0.48 W/m2K), improves the energy efficiency of buildings, reducing greenhouse gas emissions by between 15 and 58% compared to competing materials.

-

Highly resilient.

References

-

Extensive experience in the reuse of recycled rubber from discarded tyres as an aggregate for the production of new construction solutions.

-

Experts in energy efficiency, sustainability and the development of new construction materials.

-

The research team has developed other patented solutions.

Stage of development

-

Concept

-

Research

-

Lab prototype

-

Industrial prototype

-

Production

Contact

Neoblock contact

J. Adán Sánchez Reséndiz, Francesca Olivieri

e:

e:

UPM contact

Innovation and Entrepreneurship Programmes

Technological Innovation Support Centre (CAIT) – UPM

e: