Brief description of the technology solution and the added value it provides

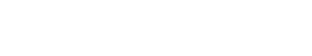

A UPM´s researchers group has developed a new and innovative bulkcarrier ship self-discharging system. The system itself it´s continuous type and uses adapted bucket wheel reclaimers plus conveyor belts placed on the cargo holds of the ship. MoSSt uses a innovative mobile stool system that protects self-discharging gear from cargo during navigation. At the same time the mobile stool system allows full access to the self-discharging gear, in order to guarantee complete cleaning of the cargo hold. That ensures complete independence from port´s terminal at the time that the ship without losing cargo hold capacity compared to a conventional gearless bulkcarrier. This is possible because the self-discharging gear is located on the lower stools present on any bulkcarrier. This solution skips the cargo hold capacity loss associated to continuous type self-discharging bulkcarriers, having at the same time the independence from port terminals common to continuous type self-discharging bulkcarriers.

Description of the technological base

Mobile Stool System, MoSSt, it´s a technical solution for continuous type self-discharging bulkcarriers of new design that uses the lower stools to accommodate the self-discharging gear. The lower stools are present on the cargo holds of conventional bulkcarriers.

For this reason there is no cargo capacity loss in the ship´s cargo holds, comparing it to a conventional gearless bulkcarrier. At the same time have all the advantages on flexibility and port independence from the continuous type self-discharging bulkcarriers.

The system uses new design mobile stools that makes possible for the self-discharging gear easy access every corner of the cargo hold. This technology can be adapted to all bulkcarrier sizes, from Handysize to Cape size, without imposing ship´s hull further conditionings. The innovative system can reduce the time to discharge bulkcarriers, improving ship´s productivity.

‘‘This technical solution is adaptable to all bulkcarrier´s sizes, meaning a new generation of bulkcarriers”

View from a bulkcarrier fitted with Mobile Stool System – MoSSt

Market demands

- The continuous type self-discharging bulkcarriers, are capable of operate in ports with small infrastructure. On the other side there is a cargo hold loss that occurs with this systems, specially on the gravity type. That means higher freight prices compared to conventional bulkcarriers.

- The discontinuous type self-discharging bulkcarriers, needs bulldozer stacking in the cargo holds. As a result the these bulkcarriers are not fully independent from port.

- A new bulkcarrier should have complete independence from port facilities and having at the same time the cargo hold geometry from a conventional bulkcarrier. Having those features together will help to reduce port associated costs and also it will maximize cargo on each trip, increasing productivity.

- Self-discharging gear shouldn’t be in contact with the bulk or weather during navigation and not to condition ship´s hull shape. The self-discharging gear also has to be cost competitive, easy maintenance and minimum power consumption.

‘‘The system joint advantages from continuous type self-discharging gear and have at the same time the cargo capacity from a conventional bulkcarrier’’

Competitive advantages

- The system has all the advantages from continuous self discharging bulkcarrier, but without the inconveniences that those systems carries out with it, such as the cargo hold capacity loss.

- The system uses the lower stools spaces to house the continuous self discharging gear.

- The system allows the ship to be fully independent for port facilities.

Combined use of stacker and reclaiming continuous system, such as adapted bucked wheels and conveyor belts that reduces reducing technical risks.

- Mobile lower stool that protects self discharging gear from bulk.

Full access to self-discharging gear during navigation and discharge, for maintenance or inspection. - A cost competitive, reliable and easy to maintain self-discharging gear, that need minimum power to operate

- Higher discharging ratios, compared to available market systems, that reduces costs and increases productivity.

Previous references

- Researchers group with experts in maritime traffic, port management, ship building and ship ´s maintenance and exploitation.

- Research and develop of innovative mechanical and automatic systems with market implementation.

Intellectual property

- Patent pending, Spain [P201430138]

- International patent request [PCT/ES2015/070074]

Development stage

- Concept

- Research

- Lab prototype

- Industrial prototype

- Production

Contact

Contacto MoSSt

José de Lara Rey; e:

Sergio Olmos Guío; e:

Contacto UPM

Área de Innovación, Comercialización y Creación de Empresas

Centro de Apoyo a la Innovación Tecnológica – UPM

e: innovacion.tecnologica@upm.es