Brief description of the technology solution and the added value it provides

LightStick consists of low-cost adhesive optical waveguides for rapid and easy formation of short distance interconnections. These flexible optical connections can be implemented as strips of varying length with integrated planar optical coupling elements, so that the user can select and/or create specific configurations for his/her particular needs. Commercial applications include those of plastic optical fibers (POFs), such as: chemical and physical sensors, short distance and low speed interconnections for electronic and electromechanical instrumentation, automotive and aerospace applications, etc. In particular, as a sensor, LightStick can be employed for liquid quality control and environmental monitoring.

This project was funded by “Convocatoria 2015 de Ayudas Fundación BBVA a Investigadores y Creadores Culturales.”

Description of the technological base

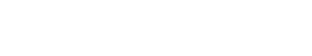

LightStick is a new type of optical connection based on an adhesive tape that contains flexible diffractive components for (de)coupling light. Distinctive features of LightStick are 1) the use of conventional Scotch tape as a low-cost, adhesive and flexible optical waveguide, and 2) the integration of planar and flexible coupling elements into the waveguide. These integrated components allow the user to inject/extract light perpendicular to the waveguide by simply sticking the tape to the light emitting (or detecting) device (for example, an LED); this cannot be carried out by means of the butt-coupling method typically used in POF applications. Perpendicular coupling avoids mechanical manipulation and destruction of the waveguide (cutting and polishing), which facilitates waveguide-emitter/detector assembling.

“LightStick allows the user to connect an optical waveguide to a light emitting device quickly and easily, neither needing complex and sophisticated tools nor technical knowledge”

Market demands

- In most POFs applications, light injection is achieved via the butt-coupling method, which requires cutting and polishing operations using specialized tools and proper optical alignment instrumentation between the fiber and the light emitting device. This can be a drawback when a set-up or repair must be implemented in a short time or by non-trained users.

- Commercial POFs exhibit a cylindrical geometry, which makes difficult direct optical coupling to planar light emitters and detectors such as LEDs and laser diodes.

- Typically, geometry and dimensions of commercial POFs are standard values; therefore it is difficult for the user to modify them or create new guiding configurations with geometries better suited to his/her needs.

Competitive advantages

- Easy and rapid coupling between the plastic waveguide and the emitter device, neither needing cutting or polishing the waveguide nor using complex alignment instrumentation.

- Planar geometry facilitates direct connection to optoelectronic devices such as LEDs, laser diodes and photodiodes.

The user can determine the waveguide dimensions and geometry by using conventional tools such as scissors or an scalpel. - Spectral filtering. The coupling elements of LightStrick allow the selection of specific light coupling according to its color (wavelength). This is not possible by using the traditional butt-coupling method.

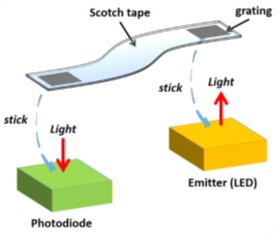

- Examples of recent applications of LightStick include the determination of refractive index of liquids and liquid level detection.

“At present, the capabilities of LightStick to be used as an optical biosensor for biomolecule detection is under study. This could open the door to new business opportunities in key sectors such as the Biomedical field (antibody, DNA detection)”

Development stage

- Concept

- Research

- Lab prototype

- Industrial prototype

- Production

Contact

Contacto solución tecnológica

Carlos Angulo Barrios

e:

w: http://www.isom.upm.es/

Contacto UPM

Área de Innovación, Comercialización y Creación de Empresas

Centro de Apoyo a la Innovación Tecnológica – UPM

e: