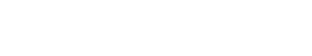

Hydrodynamic tests with both ship and marine platforms models.

CEHINAV: Model Basin of the ETSI Navales – UPM

Calm water model basin, 100 meters long, 3.8 m. wide and 2.2 m. deep with unidirectional generator of regular and irregular waves and a towing carriage.

Description of services offered

Carrying out experimental campaigns and hydrodynamic studies for ships, marine devices and platforms models used in offshore activities to obtain energy in the field of renewables and oil & gas.

These campaigns and studies can include the phases of:

1) Model construction

- offshore platforms for floating wind energy

- offshore platforms for oil & gas

- merchant vessels

- leisure craft

- wave energy converters devices

- Passive anti-roll tanks

All the models constructed at CEHINAV milling center are in accordance with the requirements of the ITTC (7.5-01-01-01) regarding models manufacture used in model basins for hydrodynamic experimentation.

2) Tests:

- towing

- seakeeping

- propulsion

- streamlines

- decay

- forced oscillations

CEHINAV has a Quality Management System for the execution of the tests certified by the Entity LGAI Technological Center, S.A. with No. EC-4738/09 in accordance with the requirements of the ISO 9001: 2015 standard.

Needs, demands and applications

To face the Asian hegemony and specifically the Chinese giant in shipbuilding, the European Union is committed to continuing with the strategy of centralization in market niches with high added value and highly technological, such as cruise and oceanographic vessels and yachts. The size of CEHINAV facilities is optimal for testing yacht and oceanographic models without a significant impact because of scale effects.

Due to the high growth of marine renewable energies (in particular of the floating wind energy), it becomes necessary a high specialization of the offshore operations support vessels, with innovative designs adapted to these operations. For that, a deeper knowledge of its hydrodynamic behavior is needed, either through numerical / computational studies and experimental campaigns in facilities such as CEHINAV model basin.

Energy sector in Europe is evolving towards a transition to a reliable, affordable, sustainable and competitive energy system, with the aim of reducing dependence on fossil fuels. Offshore wind energy will be essential to reach the percentage of 100% of renewables by 2050 to comply with the European commitment on energy efficiency and sustainability. For that, the worldwide electricity companies need to optimize their offshore operations (currently very expensive) to make renewable energies profitable, in addition to clean; and therefore, experimentation in hydrodynamic model basins with platforms for floating wind turbines is increasingly demanded by the industries of the sector.

Hydrodynamic tests with scale models allow:

- hull shape optimization, which implies greater energy efficiency in vessels or in the towing operation of offshore platforms and therefore a considerable saving in fuel

- acquisition of know-how related to the hydrodynamic behavior of the models, which implies an improvement in safety and efficiency in the operation of full scale vessels and floating platforms.

Application sector & area

Offshore, Maritime and Port Sector.

Naval Architecture Area.

Differential competences

The economic-financial structure of CEHINAV Group means that it can make very competitive offers in terms of cost for experimental campaigns, normally below the market price

Previous service references

See: https://short.upm.es/48cj0

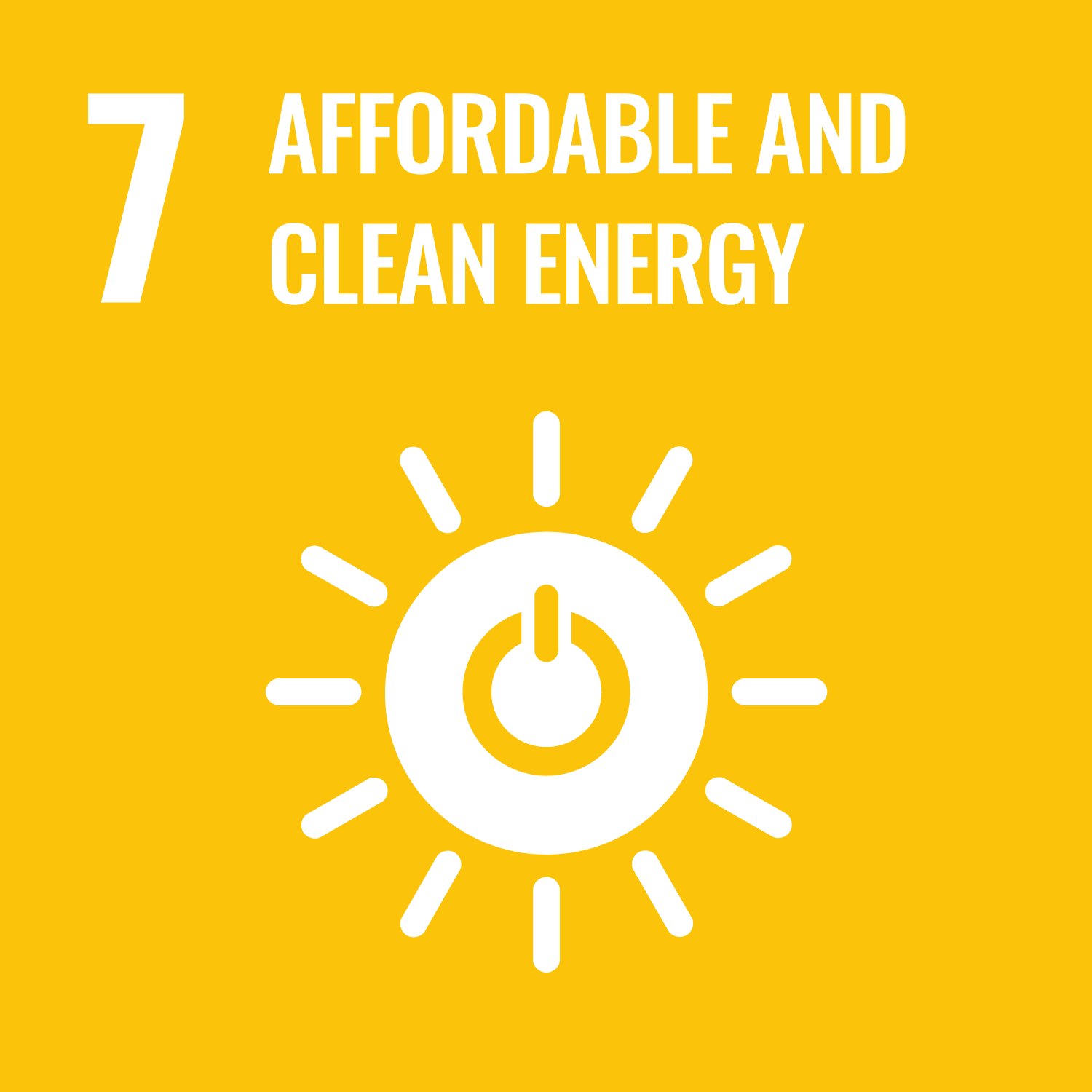

Equipment & infraestructure description

- Calm water model basin, 100 meters long, 3.8 m. wide and 2.2 m. deep.

- Milling Center ARES CNC: 5 axis; the workspace is 3600 x 1800 x 1200 mm; 12 kW liquid cooled spindle at 22000 rpm; with 8 positions automatic tool changer; CNC control is FANUC 18i. It offers a complete set of tools for the milling of wood, aluminum and almost all of the composites and engineering plastics (acrylic, polyurethane, polystyrene, ABS, Teflon etc). The precision of the milling center is up to 0.1 mm.

- Unidirectional wave generator. It is a flap-type wave generator actuated through a hydraulic system. The design, manufacturing and installation of the mechanical, govern and control mechanisms was made by VTI SL. The software used for the wave generation is AWASYS from Aalborg University. It allows to generate regular waves of up to 0.3 meters and irregular waves of up to 0.15 meters and periods of up to 7 second.

The different train of waves that can be generated are:

- Regular waves: monochromatic and stream function.

- Irregular waves: all the normalized spectrum (Jonswap, Bretschneider, etc.) with the option to define the spectrum by the user. Two generating modes: “invFFT – Random phase” and “White noise”.

- Temporal series defined by the user.

- Freak waves at a particular point of the basin.

Within the limits specified, the uncertainties in the wave height are below 3% and below 2% in the period.

- Towing carriage. In order to pull the model there is a carriage made of a steel structure which rolls on two lines of tracks anchored in the lateral parapets of the “model basin”. The alignment and leveling of these tracks have taken place with great precision to avoid alterations of the speed of the carriage during the tests. The carriage can reach a speed of up to 3.8 m/s, which allows to carry out tests for high speed vessels.

- OptiTrack: Optical Tracking Tools. This system records movements on 6 degrees of freedom of an object (displacements and rotations in X, Y and Z) by tracking a number of markers attached to the object. The technology is based on several high-speed cameras calibrated and synchronized with each other, defining a volume in which it is capture movement of that markers and. later, movement records are moved to a digital model by Tracking Tools software. The software delivers 3D matrices (x,/,z) data, which are analyzed by MATLAB.

- Forced oscillation system. This system consists on two electric FESTO linear actuators of 1.3 kW which allowing induce forced movements on 6 degree of freedom for measurement of damping and added masses. These actuators can generate a force of up 300 Kg each and induce oscillations up 2,5 Hz.

Service request

To request an offer / budget contact by email to: