Laser Micro and Nano-manufacture service

The Laser Micro and Nano-manufacture service has all the equipment needed to study, set the parameters and carry out laser processes with micro and sub-micrometric dimensional tolerances in any kind of material.

Description of the services offered

Pulsed lasers with pulse widths between fs and ns are optimal tools for processing materials with micro and sub-micrometric resolutions. Controlling a short interaction time, along with suitable selection of the wave length to be used depending on the material, and a proper beam handling and control strategy, enable the thermal load used in eliminating material to be minimised, in such a way that the extreme tolerances in production can be achieved. Moreover, the available in situ infrastructure for process profiling (SEM, confocal and Raman, etc.) gives an added value to the Service as it is able to make a detailed study using different techniques on the state of the material after processing. In addition, the UPM Laser Centre not only has more than 20 years experience in developing these types of processes, but is also a specialist in scaling up the process for integration into production lines, if required.

Needs requested and applications

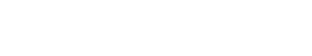

The infrastructure available currently makes it possible to process and profile all kinds of materials. Some examples of the processes that are regularly carried out are thin film processing for use in photovoltaics and electronics (insulation, interconnection, selective ablation and structuring). Modification to surfaces for their functionalisation (hierarchical structures for wettability control, surface roughness control for biomedical applications); cutting materials to create masks for microscopy and photolithography; producing channels for microfluid devices using laser ablation; laser cleaving silicon; surface modification with laser to control optical properties; and generating periodic structures induced by laser with nanometric resolution for light control, etc.

Sector or area of application

Laser Micro and Nanomanufacture processes are essential for developing new technology and devices in any strategic industrial field, from energy to biomedicine, passing through automation, the aerospace industry or textiles, amongst others. These techniques also fit in perfectly with the production philosophy and methodologies of digitised industrial environments (Industry 4.0), for which reason significant growth in the use of this technology is expected in the next few years.

Differential skills

The UPM Laser Centre has been a benchmark, including at international level, for the development of micro and nanomanufacturing processes using lasers. A particular highlight has been its contribution to the development of processes for the photovoltaic industry and flexible electronics. Its membership of the Appolo HUB European Laboratories Hub (www.appolohub.eu) also gives it a unique vision and experience of the development of this technology at international level. The Hub, created after the Appolo FP7 project, acts as a structure for validating laser processes based on pulsed lasers, helping to cover the entire European laser technology value chain, from manufacturers and equipment suppliers to industrial end users.

Previous references for provision of services

The UPM Laser Centre has been providing this Service non-stop since it was set up in 1998, mainly under contracts via Article 83 of the Organic Law on Universities, to private companies and participants in consortia for large-scale public/private collaboration projects. Some examples of leading companies and Research Centres in the industries using the service are, amongst others, as follows: Lucent Technologies, Abengoa Solar, Modragón Assembly, Power Alstom, Fagor Automation, Maier, Ecotecnia, T-Solar, Onyx Solar, Lasing, and Biod, etc. In addition, a significant number of Technology Centres OPIs and Universities have used the work of the infrastructure, including the following: ISCIII, Ciemat, UC3M, UB, UPC, URJC, and UPC, etc. The UPM Laser Centre¿s experience is unique at Spanish level, and is backed up in Europe with its membership of the Appolo laboratories Hub (www.appolohub.eu), which was created to see to the needs of European industry in the field of validating laser processes based on high-speed sources.

Equipment description

The Service currently has pulsed laser sources in fs with a programmable pulse width of 1030 nm (EKSPLA Femtolux 30), ps at 355nm, 532 nm and 1064 nm (LUMERA Super Rapid and Spectra Physics Vanguard) as well as several sources of ns at 355, 532 and 1064 nm (including a high strength UV source). All the lasers are built into machines or processing benches and there are scanners, control and beam-form control and various focussing systems in order to use any kind of material irradiation strategy and simulate processing conditions in production environments. The service also has the instrumentation needed to profile the processes in situ, including a Hitachi 3000N SEM microscope, a Leica DCM 3D confocal and interferometric microscope and a Raman Renishaw in Via microscope.

Request for service

The service can be requested by sending an e-mail to the Centre¿s general e-mail: or to its Head of Administration: . In default, any clarification can be requested from any members of Management who can be found on the Centre¿s web site: www.upmlaser.upm.es.

On first contact the e-mail should contain detailed information about the following:

- Applicant¿s contact details

- Materials in question

- Type of process to be carried out

- Process speeds and tolerances to be obtained

- Type of profiling required

With this information, the officers at the Laser Centre will contact the applicant to get all the possible details to enable the issue of a formal quote which, after acceptance by the applicant, will lead to the work being carried out under on of the forms of contract provided by the UPM.