Analysis of hydrogen, oxygen and nitrogen in inorganic materials.

This service enables measurements to be taken in steel, refractory metals and other inorganic materials.

Description of the services offered

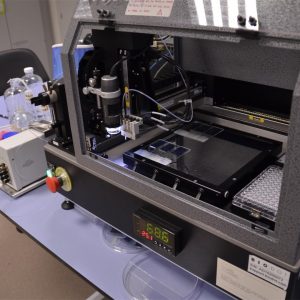

Total hydrogen, oxygen and nitrogen analyser in inorganic materials, by the inert gas fusion method using helium or argon as the carrier gas. Enables measurements to be taken in steel, refractory metals and other inorganic materials. The equipment is currently calibrated to take measurements in steel and zirconium samples using argon as the carrier gas.

Needs requested and applications

Precise measurement of the hydrogen content is key to researching the embrittlement phenomena which this element causes in structural materials, which is of great interest in the hydrogen economy.

Precise measurement of the hydrogen content is key to researching the embrittlement phenomena which this element causes in materials. It is of particular interest in measuring hydrogen content in steel, or in zirconium alloys, where one of the degradation mechanisms is the formation of zirconium hydrides.

Sector or area of application

This service is of interest to businesses and research centres working with structural materials, or who have an interest in the area of Materials Science.

Differential skills

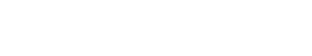

The equipment used, an LECO OHN836 analyser, enables the hydrogen content in refractory materials to be measured. This is a differential feature, because the majority of available analysers do not enable measurements to be taken in materials with a high fusion point, such as zirconium.

Previous references for provision of services

The service has been used by members of the CIME to measure hydrogen content in zirconium alloys for the European project EURAD – European Joint Programme on Radioactive Waste Management (https://www.ejp-eurad.eu, Grant Agreement number: 847593 ¿ EURAD ¿ NFRP-2018).

Equipment description

The equipment (LECO OHN836) is housed in the Structural Materials Research Centre (CIME), located in the Materials Science Department at the Higher Technical School for Roads, Canals and Ports Engineers at the UPM.

The experimental procedure consists of placing a sample, that has been weighed beforehand, in a graphite crucible which is heated in an impulse furnace to free the gases in the sample. The oxygen reacts with the graphite crucible to form CO and CO2. The carrier gas (in this case high purity helium or argon) pushes the gases freed through a mass flow controller and a series of detectors. CO and CO2 are detected using a non-dispersive infra-red sensor (NDIR). Afterwards, the gas flows through a reactant at high temperature where the CO oxidises to form CO2 and the H2 oxidises to form H2O. The gas continues through another group of NDIR cells where the H2O and CO2 are detected. Finally, they are both eliminated from the carrier gas stream, leaving the final analyte, the nitrogen, as the sole impurity. This is detected using a thermal conductivity sensor (TC).

Request for service

Requests for use of the equipment should be sent to the CIME e-mail (). The Excel file ‘Hoja_solicitud_analisis_ONH.xlsx’ (which can be downloaded in the Documentation section) should be filled in, indicating the applicant¿s details and the features of the samples and measurements to be taken. The duly completed file should be attached to the e-mail requesting the service.

The request will be assessed by the service¿s Technical Officer, who will issue a quote (including the estimated timeframe for carrying out the tests) and will send it to the applicant. In the event that any clarifications are needed, the technical staff will get in contact with the applicant.

If the applicant agrees with the terms of the quote, they should send a purchase order to the CIME e-mail (), which will take charge of processing the agreement with the Technology Transfer Office (TTO) at the UPM. Subsequently, the applicant should send the samples, properly labelled, to CIME¿s address at: HTSE Roads, Materials Science Department c/ Profesor Aranguren, 3. 28040 Madrid, for the attention of Miguel Cristóbal Beneyto. Once the analysis has been completed, the results will be sent to the applicant by e-mail.