Description of Services Provided

- Structural stability of rubble mound breakwaters.

- Functional stability of vertical breakwaters.

- Structural stability of vertical, composite, and special breakwaters.

- Functional stability of vertical, composite, and special breakwaters.

- Diagrams of pressures in vertical breakwaters and crown walls.

- GBS structural stability in offshore wind energy.

- Functional stability of GBS in offshore wind energy.

- Structural stability of floating structures in offshore wind energy.

- Functional stability of floating structures in offshore wind energy.

- Energetic behavior of pieces, reflection, transmission, and dissipation

Field of application

- Maritime Hydraulic Engineering

- Marine Engineering

- Offshore Engineering

- Port and Coastal Engineering

- Wind farm technology

Differential Advantage

Existence of a wave flume facility with a channel and test tank for wave tests with research criteria like that of the Center for Studies and Experimentation of Public Works (CEDEX) belonging to the Ministry of Transport, Mobility and Urban Agenda or the Hydrodynamic Experiences Channel (El Pardo, Madrid) attached to the National Institute of Aerospace Technology of the Ministry of Defense of Spain.

Examples of previous references

Among the most important references include:

Service for carrying out the Tests of the Physical Model Study Project on the Evolution of Damages in Sloping Breakwaters in the Ports and Coasts Laboratory of the E.T.S.I. of Roads, Canals and Ports of Madrid (2022). Client: Center for Studies and Experimentation of Public Works. Center for the Study of Ports and Coasts. CEDEX-CEPYC.

Test campaign for a GBS-type offshore device with Elisa technology for the use of wind energy (2022). Client: Esteyco, S.A.

2D reduced-scale physical model tests for the functional study of the breakwater of the Club Nàutic S’Estanyol (2022).

Tests with a 3D reduced-scale model of the Reinforcement Project of the shelter Dock of the Port of Ondárroa, Vizcaya (2021). Client: Técnica t Proyectos, S. A. TYPSA.

Optimization of a floating structure type Triwind Archimedes (2021). Client: Beridi Ingenieros, S.L.

Expansion of the tests in a 3D physical model of a hybrid gravity-floatation TRIWIND FLOAT wind turbine (2020). Client: Beridi Ingenieros, S.L.

Test on a 3D three-dimensional physical model of a TRIWIND FLOAT hybrid gravity-floatation wind turbine (2019). Client: Rover Maritime, S.A.

MADAME: Development and validation of highly durable materials for their application in maritime structures and ridges vulnerable to Climate Change. CHALLENGES (2018 – 2022).

Equipment description

In the Escuela Técnica Superior de Ingenieros de Caminos, Canales y Puertos de la Universidad Politécnica de Madrid (UPM), in the second basement, is located the “Environment, Coast and Ocean Research Laboratory (ECOREL – UPM)” installation whose objective is teaching and researcher in the field of experimentation in a physical model on a 3D and 2D scale of maritime, port, coastal works and installations at great depths of oil and gas, as well as marine energy in all its resources (wind, waves and current).

It intends to follow the conceptual and innovative footsteps of illustrious and brilliant professors of the Chair, such as D. Ramón Iribarren or D. Pedro Suárez Bores. The infrastructure falls within the homonymous Research Group consolidated by the Polytechnic University of Madrid since 2005, and has been rehabilitated, remodeled, and improved during the period from 2007 to 2017 through the University-Business Chair “Cátedra Pablo Bueno Civil Engineering of the Sea”. At present, and after the completion of the Agreement in 2017, it is part of the Department of Civil Engineering: Hydraulics, Energy and Environment with a marked teaching and research aspect.

The facility and its equipment

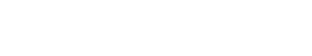

The laboratory consists of a channel and a multidirectional wave tank. The first one is 52 meters long, with a cross section of 1.50 meters wide by 1.00 meters high and has a capacity to generate regular and irregular waves of up to 0.45 m at a depth of up to 1.00 meter. It presents active absorption control of the reflected waves.

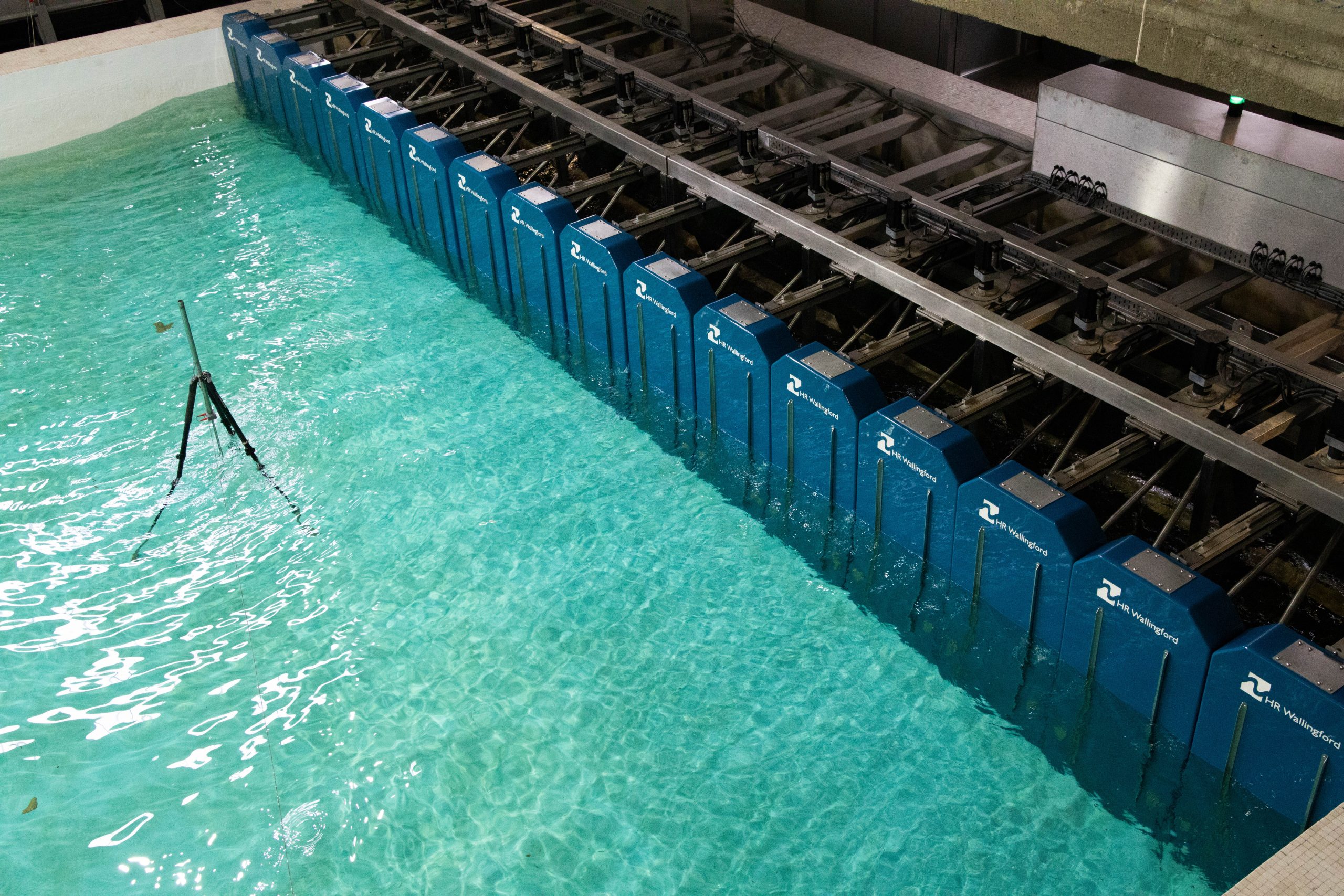

The multidirectional wave tank, which occupies the central part of the laboratory, has a depth of 1.36 meters, a width of 11 meters and a length of 33 m. The bottom of this is finished with “in situ” terrazzo paving and the vertical walls in continuous tile, it is equipped with a reflection control system through a passive parabolic ramp using 10 ppi polyurethane foam.

Multidirectional waves are generated with active absorption control, with individual movement of each blade, being able to fill up to 1.00 m.

The wave generating device is made up of 16 paddles 0.70 meters wide and 1.40 meters high, with the following average performance: H = 0.45 m in a 0.80 m sheet of water. The generation possibilities are immense since it can reproduce any conventional spectrum, that is, Pierson Moskowitz (PM), Hasselmann et al, Jonswap (J) or TMA, in addition to being able to introduce any signal from the time series of data from measurement without interruption at any target point.

As more representative details can be specified:

The laboratory has a total of 2,100 m² divided into 1,000 m² of test hall; 450 m² in classrooms, offices, and museum; 400 m² of workshops and storage areas; 250 m² of lower tank and combined service galleries for recycling and water management that, with the facilities described above of a 33 m x 11 m x 1.36 m multidirectional wave tank and a 52 m x 1 m x 1.5 m wave channel complete East.

In addition, there are service facilities consisting of a clean room; a CNC room; a workshop; a warehouse; loading bays and meeting rooms, classrooms, and offices.

The tank presents a generation of multidirectional waves capable of reproducing up to 0.30 m of wave height and wave periods of 4 s. For the channel, the generation is carried out by means of a single piston blade designed and manufactured ad-hoc by HR Wallingford. This is equipped with a reflected wave absorption and control system.

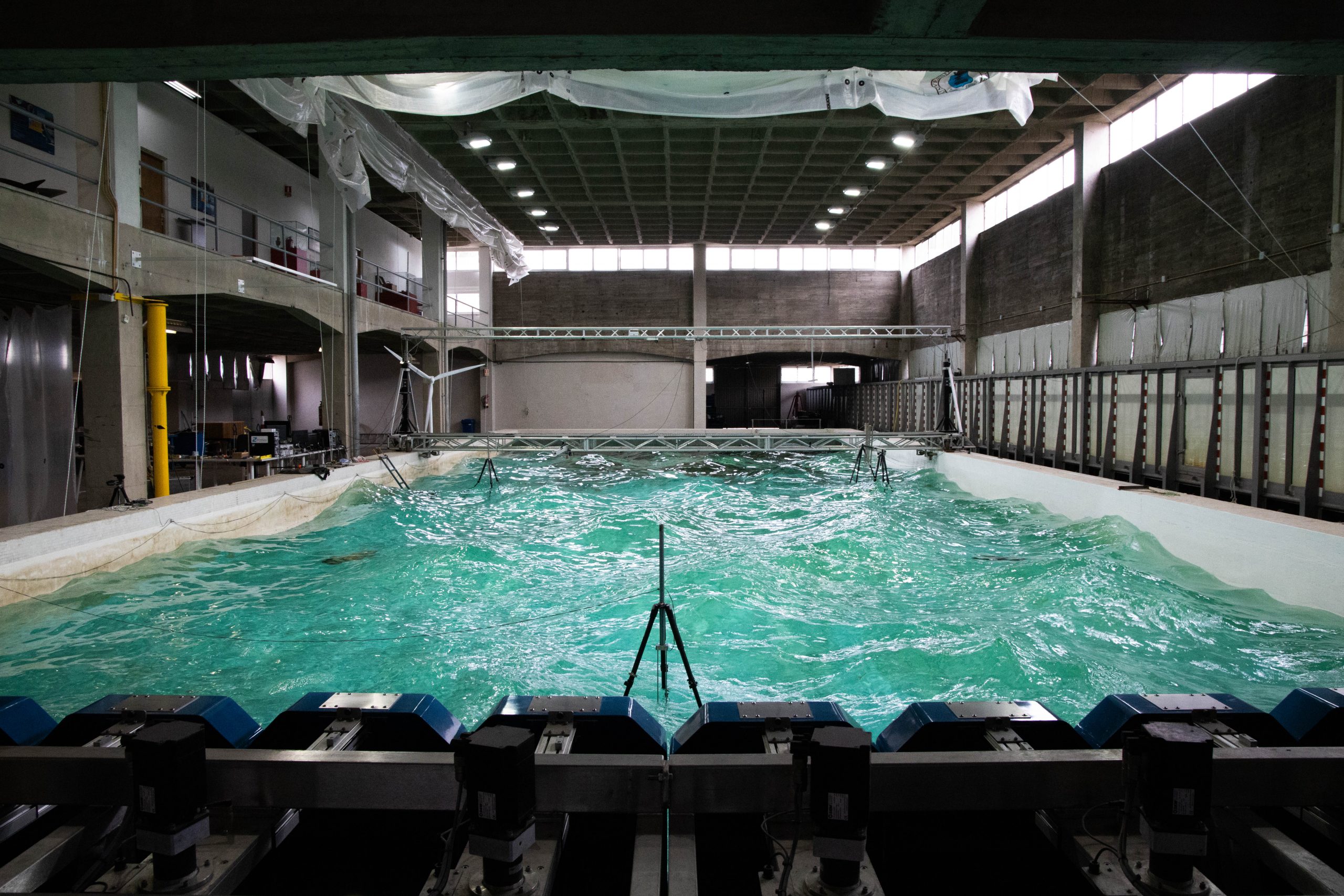

The computerization of the wave generation and calibration process is made up of a workstation, communication cards, converter units and an interface with a connection card for a minimum of eight analog input channels in differential form or sixteen channels in common form and two Also analog output channels. The facilities are complemented by equipment for wave measurement, programming and calibration, data acquisition and analysis, and a small calculation center with contrast mathematical and numerical models.

Regarding instrumentation, it provides:

- Real-time dynamic positioning and tracking system through infrared light reflection (Optitrack)

- Level sensors (Capacitive, resistive, and acoustic)

- Pressure sensors (Monoaxial and multiaxial)

- Video-image cameras

- Acoustic speed sensors (ADVs)

- Accelerometers and inertial systems (IMUs)

- Wireless communication and synchronization cards

- Topographic tools

- Photogrammetric tools

- Slow-mo. cameras

- Submersible cameras

- Acquisition system for level probes up to 400 Hz

- High resolution camera

- High performance drone for work

How to apply

The requests are based on the catalog of services, the main ones being the following:

- Structural and hydraulic stability of rubble breakwater, uncertainty, and failure modes for conventional layers of natural riprap, cubes, concrete blocks, and special pieces. Diagrams of pressures and forces in shoulders. (2D).

- Structural and hydraulic stability of vertical breakwaters, uncertainty, and failure modes for monoliths. Pressure and force diagrams. (2D).

- Energetic behavior of parts in interior works. Reflection analysis. (2D).

- Structural and hydraulic stability of breakwater, uncertainty, and failure modes for conventional layers of natural riprap, cubes, concrete blocks, and special pieces. Diagrams of pressures and forces in crown walls. (3D).

- Structural and hydraulic stability of vertical breakwaters, uncertainty, and failure modes for monoliths. Pressure and force diagrams. (3D).

- Behavior against the wave disturbance. 3D test.

- Behavior of structural and functional stability of gravity structures (GBS) for the use of ocean energy in a wind resource. 3D test.

- Behavior of structural and functional stability of floating structures for the use of ocean energy in a wind resource. 3D test.

- Behavior of ship-type floating structures against service and ultimate limit states in the repair of offshore facilities or ocean energy use. 3D test.